Featured Technology

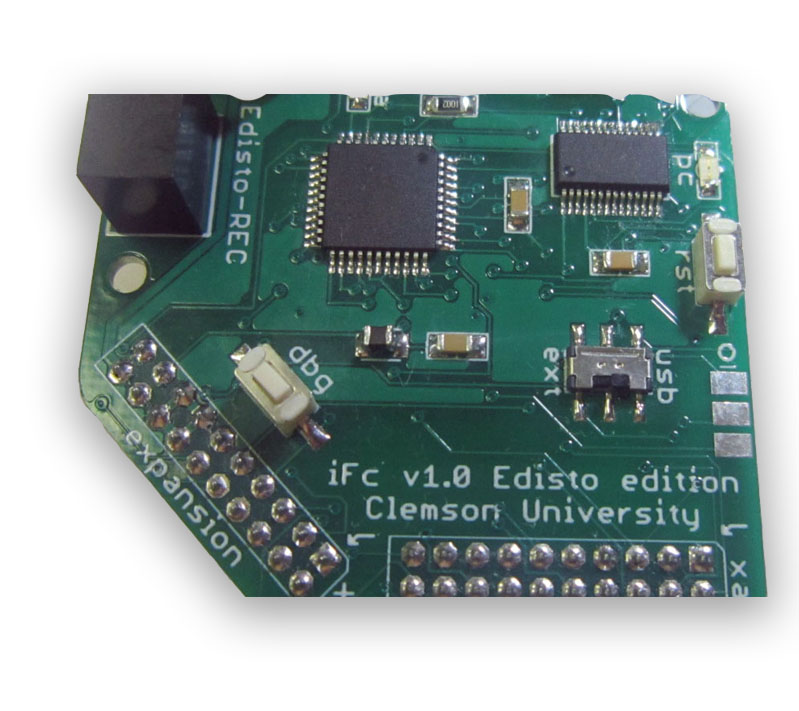

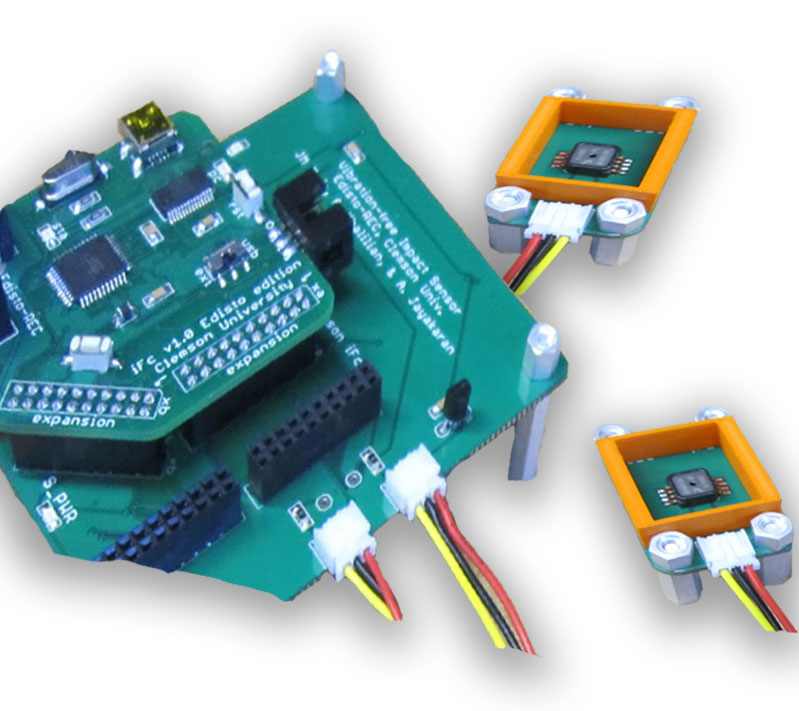

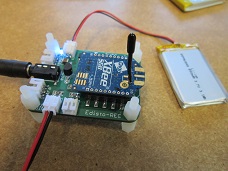

iFc

Small size controller that runs its small operating system and can be configured using a terminal program. This will be used as the primary coordinator for the Intelligent Pivot System but can also be used for other automation projects.

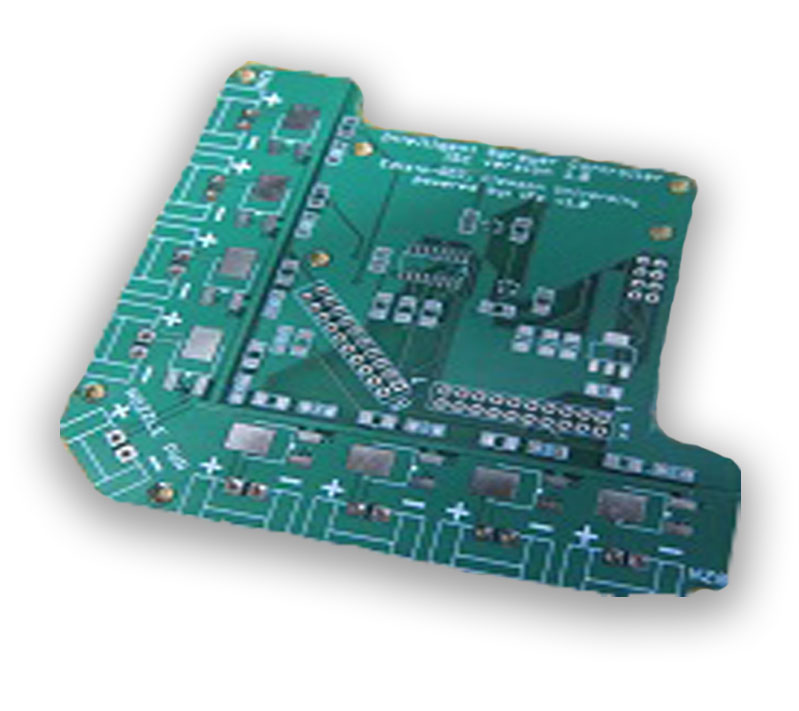

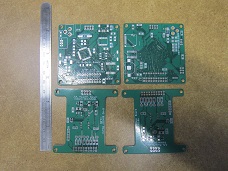

iSc

Spray controller powered by iFc can control eight individual nozzles using pulse width modulation at 10 Hz.

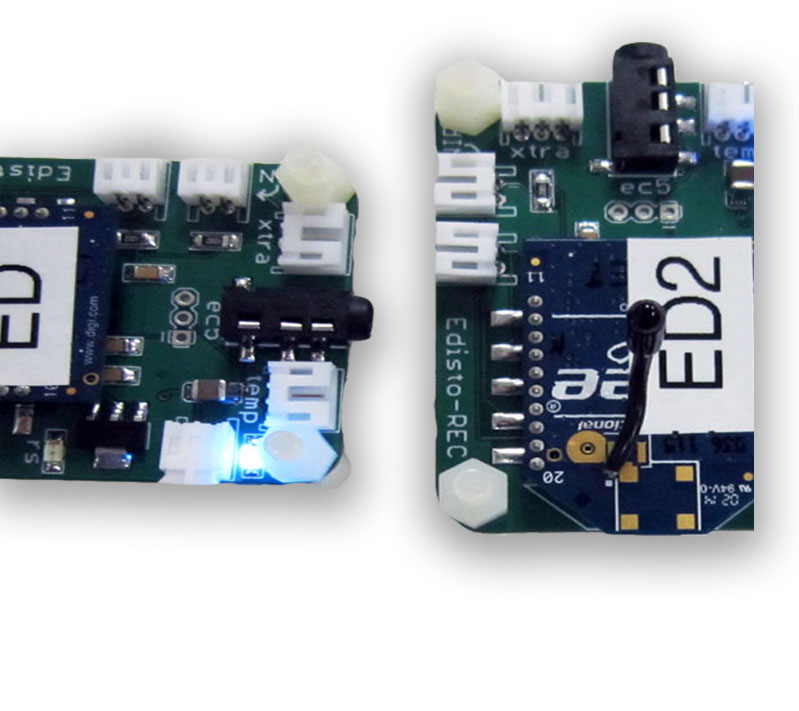

Pups

A small board (smaller than SC driver’s license) that transmits data from three different sensors into another controller, e.g. iFc or to a computer. This will be used as a part of the intelligent pivot system project.

Starch Measuring Device

A small-sized board that incorporates spectral sensors and polarized filter that measures 43 bands. This is powered by iFc derivative.

Penetro

Small-sized board that incorporates GPS, Load Cell, Potentiometer and a trigger into one platform and stream all gathered information through either wired, e.g., USB or wireless (future) through Bluetooth or Zigbee. Powered by a derivative of iFc v1.0

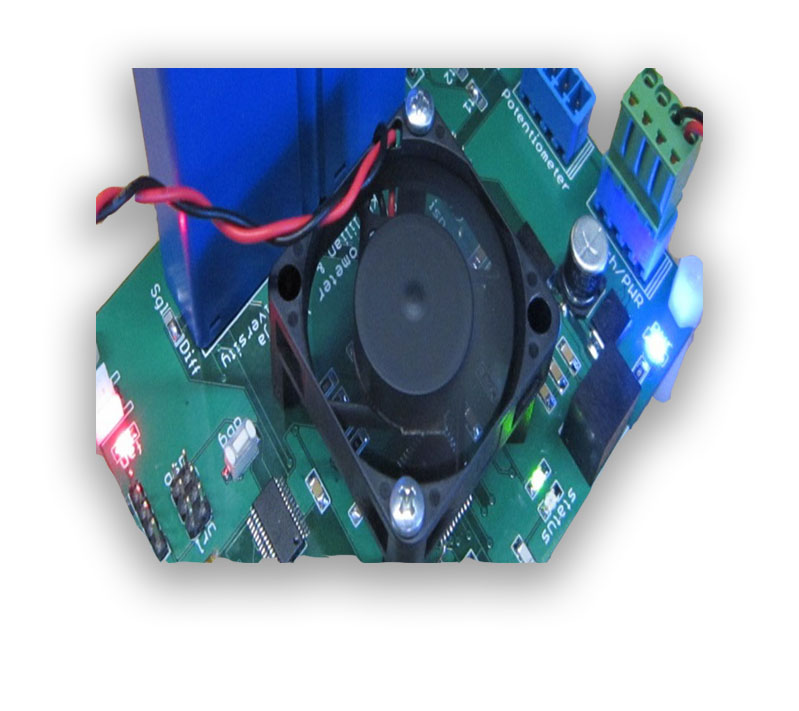

Ramp Applicator

Automate ramp application of nitrogen. Capable of being controlled either manually or automatically. Automatic control is based on the set distance for each of the spray zone. IFc v1.0 powers this controller.

4Spray Appllicator

Automate/controls for four spray nozzles. Manual and automatic control capable. Automatic control is based on the spray boom program which sends specific commands at a specified location to either turn on/off any of the four.

Pups Overdrive

This is a massive upgrade of the pups, which sends data, e.g. temperature and four soil moisture information to the cloud. Powered by iFc v1.0

pSense

This measures impact force using MEMs technology. The board comes with a wireless capability that transmit the impact force of two sensors and also saves the information directly to a microSD card.

Meet the Team

Joe Mari Maja, Ph.D.

Sensor & Automation Engineer

I am currently a Senior Researcher and Director of the Center of Applied AI for Sustainable Agriculture of South Carolina State University.

Matthew Polak

Intern

I am a Mechanical Engineeeering student – good at Math and I designed the cotton harvesting prototype. On my spare time, I design egg scanner.

Marlowe Edgar Burce, Ph.D.

PostDoc

I am working on our CURF project and Robot programming, navigation, and controls, system integration on our Cotton Inc. project.

Steward Bell

Student

I am currently working on my undergrad and hope to join the lab next year for my graduate study.

Christina Chiu

Research Assistant

Alex Steedley

Intern

I am working on testing our new soil moisture sensors and helping Dr. Burce on my free time.

Ellaina Stuckey

Intern

I am an Electrical Engineering student. I was working with the Bull tracker project with Adam Blocker and also work on our Drone project.

Dennis Daly

Intern

What We Do

This site is intended to be the portal for the Sensor Laboratory of Edisto Research and Educational Center (EREC) of Clemson University located in Blackville, SC. The laboratory is equipped with advanced machines in developing different electronic designs for EREC Research Scientist and South Carolina growers, features and his main responsibility is to develop new technologies that address current or future potential problems in SC Agriculture. Among other things, this will also features different technologies developed by members of the lab including graduate students working in the lab for their thesis.

We develop sensors, automate and deploy UAV and UGV on farms to collect important crop information.

Let's Collaborate

300 College Ave., Orangeburg, SC 29117 or jmaja at scsu dot edu

Collaborators

Visiting Scientists

Ana de Castro Mejias, Ph.D.

Remote Sensing, Spectro‐radiometry, Image Analysis, Unmanned Aerial Vehicle (UAV), Field phenotyping, Crop protection, Precision and Conservation Agriculture, Precision Horticulture, Weed Science, Mediterranean and Tropical crops, Avocado Diseases.

Jose Pena Barragan, Ph. D.

Sustainable Agriculture, Precision Agriculture, Crop Protection,Weed Science, Remote Sensing, Unmanned Aerial Vehicles (UAV), Spectroradiometry, Image Analysis, Machine Learning.

Jan Behmann, Ph. D.

I work on a project transferring sensor technology and analysis approaches for the detection and identification of plant disease from the laboratory to the field using ground-based and airborne hyperspectral measurements.

David Bohnenkamp

I focus on the detection of wheat foliar diseases using different hyperspectral sensors under controlled conditions and in the field.

Grants and Fundings

Federal

Private

Commodity

- Rapid Chicken Sex Determination with Multiple Mechanisms and Artificial Intelligence, 2018

- Adaption of Clearpathrobotics platform (Husky) for cotton harvest, 2018

- Extensive Field testing and modification of the Clemson a Water System: Next Generation of Sensor-based Irrigation, 2018

- Demonstration of a low-cost small unmanned aircraft system (sUAS) to monitor water status of container-grown woody ornamentals, 2018

- Risk Management for Current and potential users of Unmanned Aircraft Systems (UAS), an emerging technology, 2018

- Agronomic Evaluation of Virginia and Runner Type Peanut Cultivars for South Carolina, With Evaluation and Implementation of Improved Monitoring, Production and Harvest Systems – 2017

- Cooperative Intelligent Robotic Systems for Cotton Production Phase 1, 2017

- Development of Intelligent Logger Controller for Cotton Phenotyping, 2017

- Refinement and Field Testing of the Clemson Electro-Mechanical Controller for Adjusting Pump Stroke On-the-Go, 2017

- Field Testing of the Clemson Electro-Mechanical Controller for Adjusting Pump Stroke On-the-Go, 2017

- Utilizing Deep-rooted Cover Crops to Enhance Water Quality, Soil Health, and Farm Profits While Reducing Soil Compaction in Coastal Plain Region, 2017-2020

- A Variable-Rate Nutrient Management Technique for Center Pivot Irrigation Systems, 2017-2018

- Rapid Proposal: Impact of storm surge on coastal forest demography in response to repeated hurricane disturbances, 2017

- Using UAV imagery data to predict yield in a cotton breeding program, 2016

- Development of Intelligent Logger Controller for Cotton Phenotyping, 2016

- Real-time, Variable-Depth Tillage for Managing Soil Compaction in Cotton Production, 2016-2017

- Using UAV imagery data to predict yield in a cotton breeding program, 2015

- Remote Sensing with an Unmanned Aerial Vehicle to Predict Insect Abundance and Crop Injury in Cotton, 2015

- Development and Evaluation of a Sensing Device for Quantifying Water Deficit Stress in Cotton, 2015

- Development of Remote Sensing Technologies for Important Insect Pests in South Carolina Soybeans, 2015

- Utilizing Space-Based Technology to Determine Hydrological Properties of Soils, 2014-2018

- Demonstration of Innovative Nutrient Management Strategies Combined with Soil Amendments to Enhance Nitrogen Use Efficiency, Farm Profitability, and Environmental Quality, 2014-2017

J.Frank Schmidt Family Charitable Foundation

Press

Greenhouse Product News

Technology- Drones in a Greenhouse?

Nursery Manangement

A view from above.

AgProfessional

Clemson precision-ag research primed for new heights

AUVSI

Clemson granted Certificate of Authorization to fly UAS across United States.

AgFax

South Carolina: Peanut Production Guide Now Available

The Times and Democrat

DIGITIZING AGRICULTURE: Clemson opens high-tech lab at Edisto Center in Blackville

Farm Journal

Swarm Bots Could Shift Ag History

AgWeb

Robotic Harvest Gets Major Push

Southeast FarmPress

Clemson gets a blanket license to fly UAVs

Aiken Standard

Ceating the savvy farmer.

Greenville Journal

Clemson agriculture drones could boost farm production across the U.S.

Savannah Now

Farmers learn ways to check crops using drones

Publications

Gallery

Center of Applied Artificial Intelligence for Sustainable Agriculture

Public Service and Agriculture (PSA)

South Carolina State University

300 College Ave., Orangeburg, SC 29117

jmaja at scsu dot edu

COPYRIGHT 2021 iad4sc.com

Site Design by Peach Innovation LLC , Based in Aiken SC